27 Feb The cycling pad ReUp

ReUp – The eco-sustainable recycled cycling pad

The commitment to the fight against climate change is also pursued through tge work of all those companies that are and will be able to optimize production stages without negatively impacting the environment.

Virtuous recycling practices make possible to recover materials and waste materials that have reached their end-of-life, so as to raise the eco-friendly standards to which all companies, including those of cycling products, should refer.

Teosport is proud to do its part in protecting the environment, by making the first remanufactured eco-friendly performance pad for cycling shorts.

Eco-friendly bike pads: why they are so important

The goal was achieved after some time, mainly due to the company’s vertical business structure that carries out in-house not only R&D but also the production stages. Indeed, this organizational model allows constant control of the production chain.

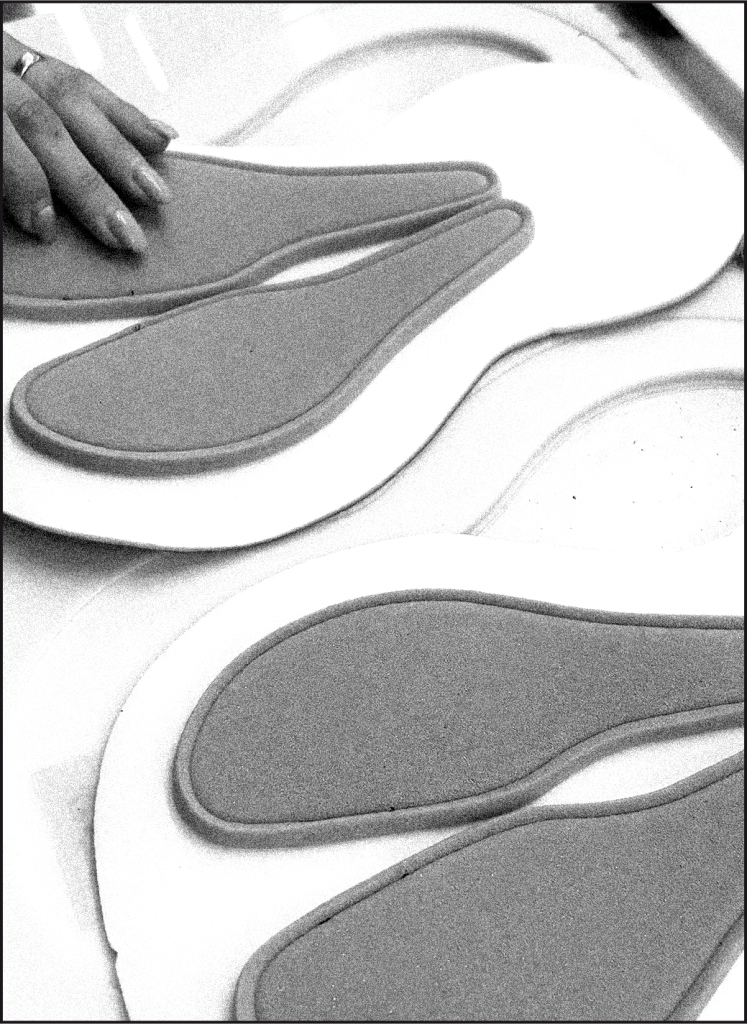

The standard pad production process involves cutting out the roll of fabric, laminated with foam, to obtain the desired product shape. Excess foam is fleshed out and the whole is shaped by heat to obtain the finished product.

The scrap resulting from the cutting and fleshing stages is collected and destined for landfill disposal as waste.

Teosport has decided to turn the discarded foam into an element that can be used to make new eco-friendly cycling pads.

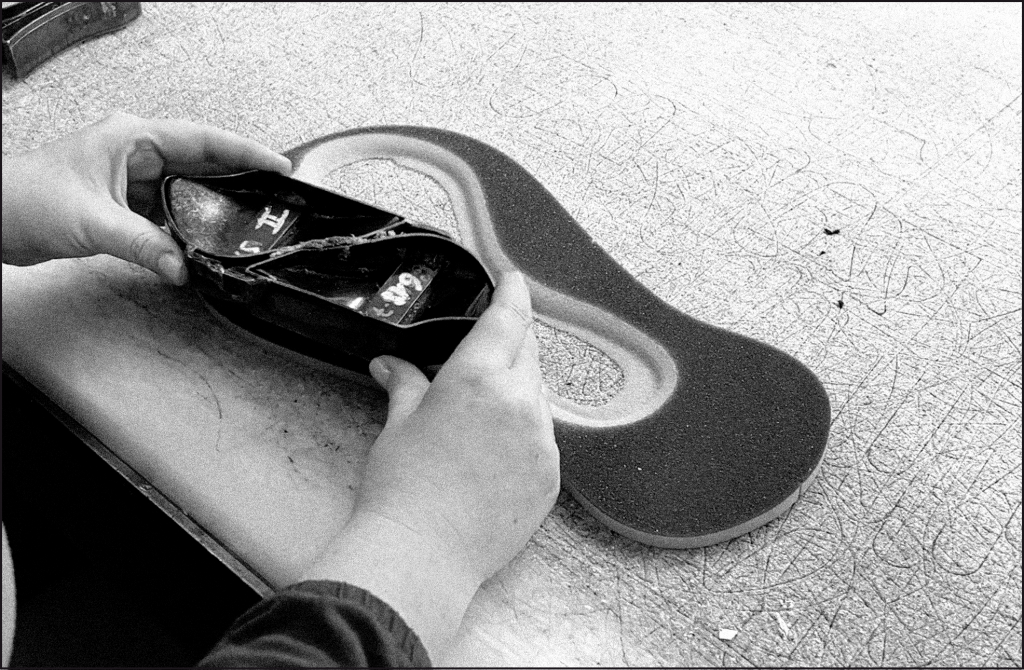

The innovative process developed by Teosport to create eco-friendly cycling pads involves recovering waste from excess foam by performing a series of processes on it aimed at obtaining new support inserts.

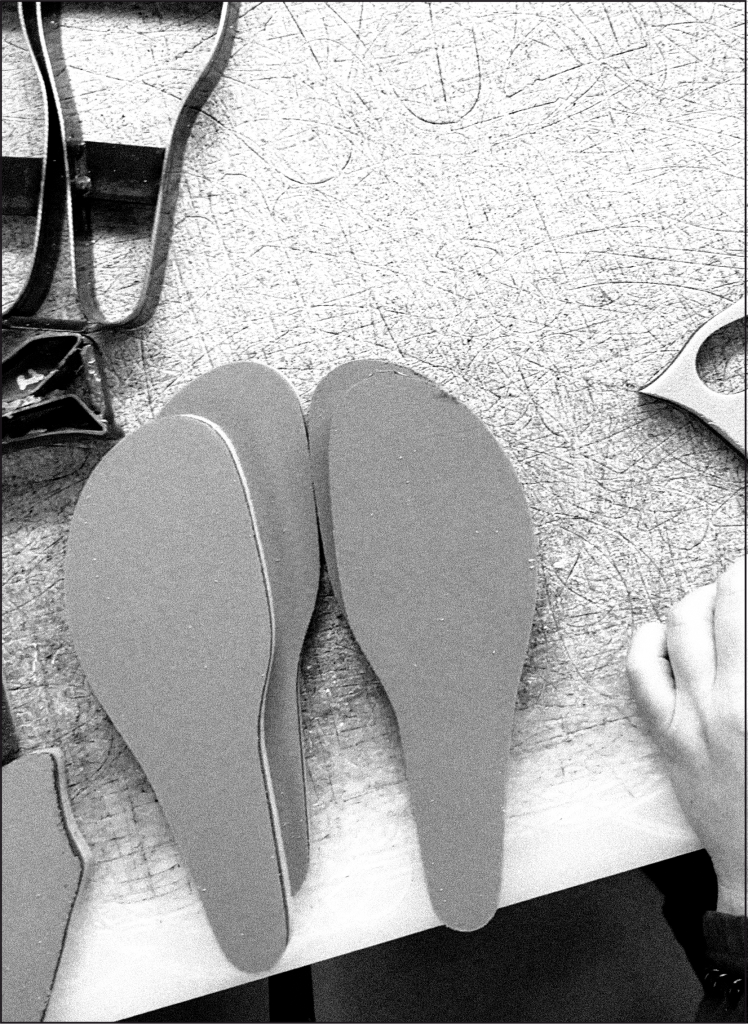

The resulting inserts, after being reshaped, are applied to bases made from recycled fabrics.

This process allows production waste to have a new life, providing excellent performance for sports cyclists and contributing to the fight against climate change.

Cycling pads are crucial accessories for cyclists’ well-being and performance: they are pads made from a combination of different materials, different shapes, and technologies to protect men’s and women’s private parts.

Teosport’s environmentally sustainable cycling pads are the result of continuous study toward innovation and sincere enthusiasm for environmental issues. ReUp was born out of the intention to extend the life cycle of materials destined for the scrap heap by making new performance pads without impacting the environment.

Thanks to the ReUp process, it is possible to recover parts of leftover materials from previous processing,remodeling new components and using them to make additional products. In this way, we are able to optimize the use of raw materials while drastically decreasing the waste to landfill.

This process also allows us to reduce the environmental impact from the normal demands of raw and semi-finished materials, transportation and production steps. From an initial estimate, the production of ReUp cycling pads allows us to reduce production waste by 90 percent.

Teosport firmly believes in the principles of circular economy and environmental sustainability, and for years has continued to do its part to bring increasingly ecofriendly cycling accessories to the market.

The process of obtaining GRS certification for ReUp pads is currently underway.